|

1919

Foundation of the company in Stuttgart by the proprietor Hermann Stahl for manufacturing soldering, welding and cutting equipment.

1925

Utility model for soldering tools with removable soldering iron as well as for welding and cutting torch handles with special single valve control.

1927

Utility model for gas tap with collecting brush in acetylene generators, for hydrogen generators and for soldering tool with replaceable torch attachments.

1928

Utility model for high-pressure acetylene generator.

1929

Utility model for soldering torch valve body with attached tip-cleaning needle and for soldering liquid bottles with brush cap. The first tests and approvals for an acetylene high-pressure generator are granted by the Prussian Ministry for Trade and Industry.

1930

Utility model for acetylene soldering gun operating according to the Bunsen principle with regulating control.

1932

Utility model for a safety valve in tank farms with unpurified gas as well as for a device to prevent the occurrence of a vacuum in acetylene plants.

1933

Utility model for gas-soldering torch with mobile hose attachment - forerunner model to the PERKEO heavy-duty soldering iron.

1934

Utility model for carbide basket featuring a groove for condensation water for acetylene generator as well as for welding torch handle with adjustable scale.

1935

Utility model for pressure reducing valve with throttle pre-stage.

1936

Utility model for gas blue torch, operating according to the Bunsen principle, comprising screen head with several bores and torch cap with lateral openings for secondary air intake - a further development in the forerunner to the PERKEO heavy-duty soldering iron. The company moves to its own factory premises in Ludwigsburg. First mention of quality control in the manufacturing of acetylene generators.

1937

Utility model for oxy-gas cutting torch with right-angled grip.

1938

Utility model for multi-component handle for welding and cutting torch. After successfully completing the quality test PERKEO is awarded licenses for acetylene generators, hydraulic seals and back-pressure valves by the German Acetylene Committee of the Reich's Ministry for Economic Affairs.

1939

PERKEO participates in the new drafting and revision of different standards in the German Standards Committee.

1942

PERKEO has its quality monitoring inspected by an external laboratory. The Welding Research Center of the Reich's Railway Repair Works in Wittenberg (Schweiß-technische-Versuchsanstalt des Reichsbahn-Ausbesserungswerkes Wittenberg) carried out this first audit.

1950

First external tests in the fields of HV safety valves through the Stuttgart Regional Economic Development Agency (Landesgewerbeamt).

1951

PERKEO supports the DVS Society (Society for the promotion of welding and allied processes) with acceptance certificates for the development of the new acetylene ordinance.

1958

Utility model for torch handle with arrestor. Death of Hermann Stahl. The management of PERKEO passes into the ownership of the founder's son, Eberhard Stahl.

1960

Production and sales of the first portable small-size welding, cutting and brazing equipment. This marked the birth of PERKEO on-site equipment which became firmly established on the market; a great relief for every fitter which meant he could now take his welding or brazing equipment with him to the workplace, putting an end to any maneuvering of large cylinders or even extensive dismantling work.

1964

PERKEO is active in the technical standards committee for pressurized gas systems at the German Standards Committee.

1972

The first external testing in the fields of cylinders for compressed gases, liquefied gases and gases dissolved under pressure is carried out by the Technical Inspectorate (TÜV) of Baden.

1980

Utility model for portable and wheeled small-size equipment for oxy-gas welding, cutting and brazing - PERKEO on-site equipment and systems.

1996

Eberhard Stahl passes on the management of PERKEO to his daughter and to the holder of general power of attorney, Yassine Hönes. Decision to introduce quality monitoring is passed and realized. It is a project for the following two years to draw up a new quality management manual including the description of the quality management system and the organization.

1997

PERKEO requests inspection with the DVGW (German Technical and Scientific Association for Gas and Water) and voluntarily harmonizes the products with the latest DVGW regulations. This technology and consequently FMEA and CAQ are introduced. Quality assurance in receiving is modernized, the results of all quality assurance measures are statistically evaluated.

1998

Prokurist Yassine Hönes becomes sole holder and general manager.

1999

The company moves to its current premises in Schwieberdingen.

2001

Filing of a Utility Model Application for the PERKEO soldering backpack - small-size equipment that can be carried on your back for oxy-gas brazing.

2003

First complete catalogue with systematic classification of the products by gas type and pplication. New to the program are the gas cartridge brazing torches and the gas cartridge. soft soldering irons. Introduction of the ZINNLUX soldering piece. Maintenance-free soldering iron with a special coating for the soft-soldering of sheet metal. Subsequent filing and hammering as well as the ammoniac stone are superfluous.

|

|

2004

Development of a nationwide sales network across Germany.

2005

First presentation of the innovative QUICKY quick-release coupling. A small propane cylinder filling system for tradesmen, which completes the filling process entirely without tools.

2007

Introduction of the novel soft soldering flux UNIGEL. The gel for every job! A geltype soft soldering flux suitable for almost every material.

2008

Expansion of the range to include the featherweight TITAN roofing torch. A tool for roofers, produced from the high quality material titanium and thus considerably lighter than conventional roofing torches. PERKEO presents a new Air conditioning and refrigeration tool program in a designated catalogue. In addition to the expanded product palette for brazing technology, special tools and measuring equipment are also available from stock.

2009

PERKEO celebrates its 90th birthday with the DELUX 90 anniversary version of its legendary heavy-duty propane soldering iron. It is fully chromium-plated and equipped with the maintenance-free ZINNLUX-LONGLIFE soldering piece as well as an attached support leg.

2010

Introducing ALUWELD aluminum welding rods for aluminum flame brazing with NASA approval!

PERKEO presents a new range of roofers and plumbers' tools in a special catalogue. The roofer catalog is born.

2011

PERKEO relies on strategic partnerships in sales. PERKEO works with the following purchasing cooperatives: ZEDACH, EUROBAUSTOFF, COBA, FDF, EDE, EIS, PLUS6, STARK Germany, HAGEBAU and EVB.

Establishment of a sales force in France with 3 sales representatives.

2012

PERKEO presents its new roofer and plumber tool catalog version 3.2. Expansion of the sales program to include the hot-air welding machines NOMAD, PANTHER and TYSON as well as the hot-air manual welding machines HOTGUN, HOTGUN ELECTRA and JUMBO with accessories such as slot nozzles, pressure rollers, knives and scissors.

2013

Expansion of the sales program with the small welding machines for propane-oxygen MINI ECO and MAXI ECO.

2014

Contract partnership with well-known welding technology distributors in Australia and New Zealand.

2015

Introducing PIRANHA – a highly active soft soldering flux for pre-weathered titanium zinc.

2016

Introduction of the patented TWISTER "sandblasting brush"!

2017

Introduction of the self-developed high-power burner TITAN BULLFIRE - The lightest high-power burner on the market! Establishment of sales in Poland.

2018

Introduction of the newly developed welding torch TECTOR TITAN as well as the tool bags MAXIMUS and BARBARIAN.

2019

100 years of PERKEO - PERKEO celebrates its 100th company anniversary!

Introduction of the aluminum soft solder ALUKING 100 and the ecological bitumen cleaner B2MAX.

2020

Introduction of the self-developed and Europe-wide patented "dragon wing" torch handle at the DACH and HOLZ trade fair in Stuttgart. This ergonomically ingenious forearm support shifts the weight of the work tool from the wrist to the entire arm. The result is a clearly noticeable relief, wear and tear on the wrist is minimized and the health burden is reduced as a result. At the same time, labor productivity increases. Introduction of the self-developed and Europe-wide patented "dragon wing" torch handle at the DACH and HOLZ trade fair in Stuttgart. This ergonomically ingenious forearm support shifts the weight of the work tool from the wrist to the entire arm. The result is a clearly noticeable relief, wear and tear on the wrist is minimized and the health burden is reduced as a result. At the same time, labor productivity increases.

PERKEO presents its new roofer and plumber tool catalog version 3.3. In addition to the "dragon wing", the patented transfer and transport aid T.RAX is new to the range.

2021

Expansion of the sales program with the practical WARRIOR burner bag.

2022

PERKEO presents its new refrigeration and air conditioning tool catalog version 2.5 at the CHILLVENTA trade fair in Nuremberg. New to the range are the patented pipe cutters EASYCUT and EASYCUT MINI as well as new special tools and measuring devices for refrigeration and air conditioning technology.

2023

PERKEO presents its self-developed UPSIDE cartridge torch at the SCHWEISSEN und SCHNEIDEN trade fair in Essen. This high-performance gas cartridge torch was specially designed for short-term use on roofs and can be used in all positions for welding edges and overlaps thanks to its “overhead function.”

2024

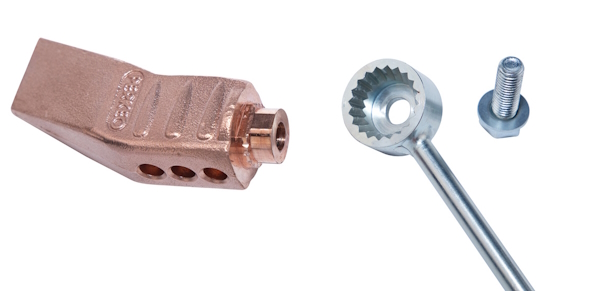

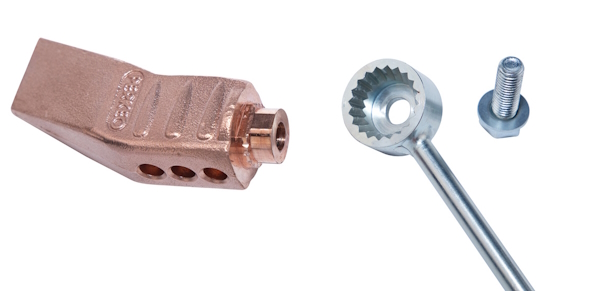

Utility model for the self-developed LOCKDOWN24 copper piece!

The new LOCKDOWN24 copper pieces eliminate a long-standing problem with conventional soldered copper pieces. In previous models, the driven-in steel retaining pin loosens after only a short period of use, causing the copper piece to wobble.

With the new PERKEO LOCKDOWN24 copper pieces, there is no more wobbly pin! The copper piece inserts are screwed firmly into the newly developed copper piece holder with an M8 screw and can be retightened if necessary. A toothing inside the holder ensures a secure hold. In addition, the copper inserts are 360° adjustable and can be replaced with new ones if necessary.

ZINNLUX LONGLIFE soldering pieces are now also available in the screwed LOCKDOWN24 version.

New: LOCKDOWN24 piston in the 500 g version, hammer-shaped and offset.

The popular AGROFIX flux has been improved and is now even stronger!

2025

PERKEO exhibits for the first time – and with great success – at the DACHFORUM trade fair in Kielce, Poland.

PERKEO introduces the new MINI ECO PRO and MAXI ECO PRO propane-oxygen brazing devices.

Newly developed: handy cartridge shrink burner with UPSIDE gas cartridge that can be used in any position, supplied in a practical case set for quick shrink applications.

Comprehensive revision and expansion of the PERKEO product range. New to the PERKEO range: micro burner hoses, twin hoses for propane-oxygen, pressure reducers for forming gas, CO², and argon, propane steel cylinder wall brackets, and various accessories.

PATENT for LOCKDOWN24 copper pieces!

|

PERKEO was the name of the court jester and dwarf serving under the Elector of the Palatinate , Karl III Philipp, in the 18 th century. The little fellow first saw light around 1702 and was baptized with the name Clemens. At sixteen he was appointed court jester by Karl Philipp. The Elector, who enjoyed the pleasures of a good wine, was impressed by the way the young Clemens was able to hold his liquor.

PERKEO was the name of the court jester and dwarf serving under the Elector of the Palatinate , Karl III Philipp, in the 18 th century. The little fellow first saw light around 1702 and was baptized with the name Clemens. At sixteen he was appointed court jester by Karl Philipp. The Elector, who enjoyed the pleasures of a good wine, was impressed by the way the young Clemens was able to hold his liquor.

Introduction of the self-developed and Europe-wide patented "dragon wing" torch handle at the DACH and HOLZ trade fair in Stuttgart. This ergonomically ingenious forearm support shifts the weight of the work tool from the wrist to the entire arm. The result is a clearly noticeable relief, wear and tear on the wrist is minimized and the health burden is reduced as a result. At the same time, labor productivity increases.

Introduction of the self-developed and Europe-wide patented "dragon wing" torch handle at the DACH and HOLZ trade fair in Stuttgart. This ergonomically ingenious forearm support shifts the weight of the work tool from the wrist to the entire arm. The result is a clearly noticeable relief, wear and tear on the wrist is minimized and the health burden is reduced as a result. At the same time, labor productivity increases.